Menu

Menu

Menu

ASME: A Pioneer in Cosmetic Tube Packaging

Heritage and Evolution

ASME traces its roots back to the 1990s as “Meida Tube,” later expanding in 2005 to establish its current identity. That same year, the company achieved ISO9001 quality management system certification. Specializing in the research, development, and production of cosmetic tube packaging, ASME is committed to meeting diverse customer needs while actively driving environmental sustainability and technological innovation.

Adapting to Market Shifts

Over the past two decades, ASME has witnessed the transformation of China’s beauty industry—from the dominance of offline retail to the rise of e-commerce, social media-driven sales, and livestream product launches. In an intensely competitive packaging market, ASME has consistently listened to customer needs, embraced innovation, and maintained a strong foothold by enhancing its competitive edge.

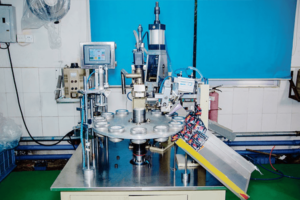

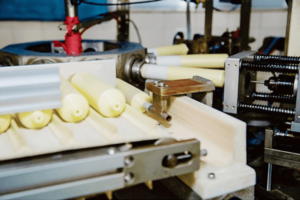

Production Strength and Quality Assurance

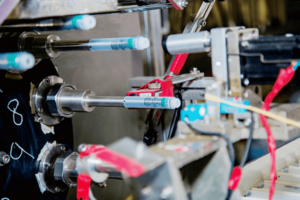

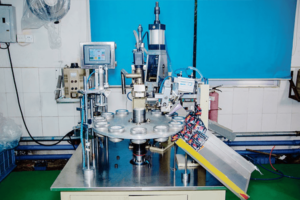

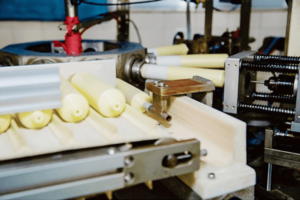

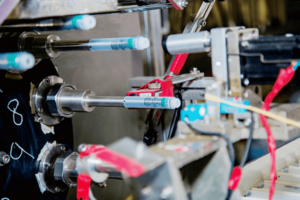

With a robust monthly production capacity of 8 million units, ASME continues to increase productivity and efficiency through equipment upgrades and process optimization, often achieving this without adding to or even reducing workforce requirements. The company ensures a reliable and high-quality supply chain for its clients. A state-of-the-art testing laboratory conducts rigorous evaluations, including yellowing, high/low temperature performance, leaking, and cap-opening force tests, ensuring exceptional quality standards.

Sustainable and Innovative Products

ASME offers a variety of eco-friendly packaging solutions, such as sugarcane tubes, PCR recycled material tubes, kraft paper tubes, reduced-plastic caps, and fully plastic pump tubes. High-end materials are also available, including five-layer PE tubes, aluminum-like tubes, textured fabric tubes, and holographic tubes. Custom mold production services are offered to meet unique client needs.

Pioneering new techniques in the industry, ASME employs innovations like photochromic/thermochromic printing, metal brushing effects, and cat-eye printing technology, providing packaging solutions that are both functional and visually striking, helping customers achieve standout market appeal.

We are known for consistently producing high-quality packaging that meets the rigorous demands of the cosmetic industry.

Our advanced facilities produce up to 80 million units annually, meeting the needs of clients of all sizes.

We are committed to innovation to stay ahead of market trends and provide modern and effective packaging solutions.

With experience and a customer-first approach, we handle every project with care and professionalism.

At Asme Packaging, innovation and quality are at the heart of everything we do. We are dedicated to pushing the boundaries of packaging design, while adhering to the highest industry standards. Our commitment to excellence and customer satisfaction has made us a trusted name in the global cosmetic packaging market.

These testimonials reflect ASME Packaging's dedication to quality, innovation, and customer satisfaction, making them a trusted partner for cosmetic brands worldwide.

We’ve been working with ASME Packaging for years, and they consistently deliver exceptional quality. Their ability to customize packaging to match our brand perfectly has been a game-changer for us.

ASME’s manufacturing capabilities are impressive. Even with large orders, they never compromise on quality or delivery timelines. A reliable partner we trust completely.

ASME Packaging helps us stay ahead of the competition with their innovative designs. Their team is proactive and understands market trends, making collaboration seamless and productive.

The ASME team is always responsive and professional. They listen to our needs and provide solutions that exceed our expectations. Truly a pleasure to work with!