Menu

Menu

Menu

In today’s fast-paced manufacturing environment, efficiency and precision are critical for success. This is especially true for companies involved in packaging small tubes, where the margin for error is slim, and the demand for high-quality products is ever-increasing. ASME Packaging Co., Ltd (ASME) has emerged as a leader in this niche, pioneering the use of automated filling machines to optimize the packaging process. In this article, we will explore how ASME’s innovative solutions are transforming the industry, focusing on the benefits of automation and the technology’s impact on operational efficiency.

ASME Packaging Co., Ltd, commonly referred to as ASME, is a renowned name in the packaging industry. With years of experience and a commitment to innovation, ASME has established itself as a leader in providing state-of-the-art packaging solutions. The company’s focus on automated filling machines has been pivotal in enhancing the efficiency of small tube packaging, a sector that demands precision and speed.

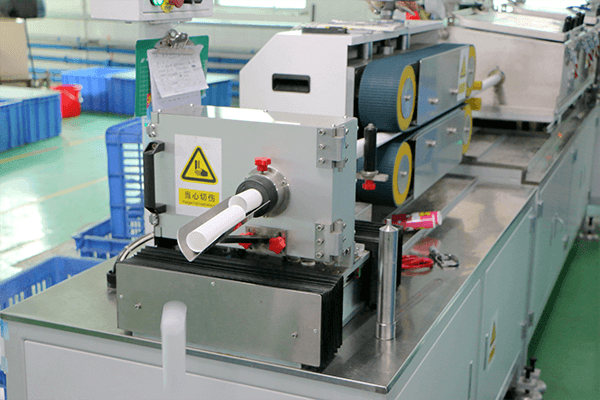

Automated filling machines are revolutionizing the packaging industry by offering unparalleled accuracy and speed. These machines are designed to handle a variety of products, from creams and gels to pastes and liquids, with minimal human intervention. This automation not only reduces the likelihood of errors but also significantly increases the production rate, allowing companies like ASME to meet the growing demands of their clients.

As the packaging industry continues to evolve, several trends are shaping the future of automated filling machines. One of the most significant developments is the integration of artificial intelligence and machine learning technologies. These advancements allow machines to adapt to changing conditions and optimize their performance in real time, further enhancing efficiency and reducing downtime.

pump cap tube packaging

d19 eye cream tube packaging

facial cleanser tube

Another trend is the shift towards sustainable packaging solutions. ASME is at the forefront of this movement, developing machines that are not only efficient but also environmentally friendly. By utilizing energy-efficient components and minimizing material waste, ASME’s solutions align with the industry’s growing emphasis on sustainability.

While automated filling machines offer numerous benefits, they also present certain challenges. For instance, the initial investment in these machines can be substantial, particularly for small and medium-sized enterprises. However, ASME addresses this concern by providing flexible financing options and comprehensive after-sales support, ensuring that businesses of all sizes can benefit from their technology.

Additionally, the complexity of operating advanced machinery can be daunting for some companies. To mitigate this, ASME offers extensive training and support services, empowering clients to maximize the potential of their automated systems.

ASME’s commitment to innovation and customer satisfaction has solidified its position as a leader in the packaging industry. By continuously improving their automated filling machines and expanding their service offerings, ASME is helping businesses worldwide enhance their operational efficiency and product quality.

As the demand for efficient and precise packaging solutions continues to grow, automated filling machines will play an increasingly vital role in the industry. Companies like ASME are leading the charge, providing cutting-edge technology and comprehensive support to help manufacturers meet the challenges of today and tomorrow. With a focus on innovation, sustainability, and customer satisfaction, ASME is poised to shape the future of small tube packaging for years to come.

In summary, ASME Packaging Co., Ltd is revolutionizing the packaging industry with its automated filling machines, offering unparalleled precision, speed, and versatility. As industry trends continue to evolve, ASME remains at the forefront, driving innovation and efficiency in small tube packaging. By addressing challenges and providing comprehensive support, ASME ensures that businesses of all sizes can benefit from their advanced solutions, paving the way for a more efficient and sustainable future.