Menu

Menu

Menu

ASME Packaging Co., Ltd, abbreviated as ASME, is a leading innovator in the packaging industry. With years of expertise, ASME specializes in designing and manufacturing high-quality custom collapsible tubes that redefine the way products are dispensed. These tubes are tailored to meet the specific needs of various industries, including cosmetics, pharmaceuticals, food, and industrial applications. ASME’s commitment to sustainability and efficiency has made it a trusted name in the global packaging market.

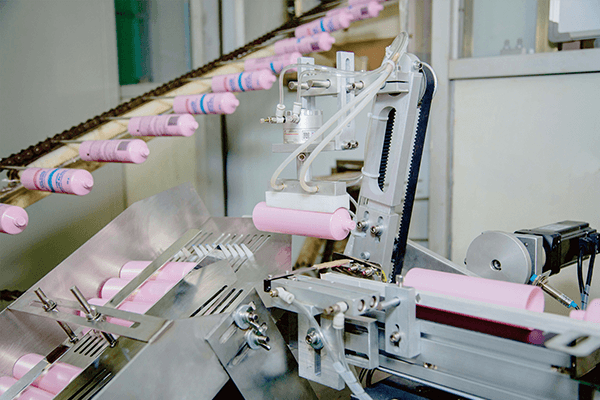

Custom collapsible tubes are versatile packaging solutions designed to dispense products efficiently while minimizing waste. These tubes are made from materials such as aluminum, plastic, or laminated composites, ensuring durability and flexibility. ASME’s collapsible tubes are customizable in size, design, and functionality, making them ideal for a wide range of applications. Whether it’s a skincare cream, toothpaste, or industrial adhesive, these tubes offer precise control over product dispensing while maintaining the integrity of the contents.

One of the primary advantages of custom collapsible tubes is their ability to dispense products efficiently. Unlike traditional packaging, collapsible tubes allow users to extract nearly all of the product, reducing waste and enhancing customer satisfaction. ASME’s innovative designs incorporate features such as nozzle customization, air-tight seals, and ergonomic shapes to ensure ease of use and optimal functionality.

ASME’s collapsible tubes are widely used across multiple industries, each benefiting from their unique features. Below are some key applications:

In the cosmetics industry, collapsible tubes are ideal for packaging products such as creams, lotions, and gels. The precision dispensing feature ensures customers can use the product efficiently, while the customizable designs help brands stand out on retail shelves. ASME’s eco-friendly materials align with the growing demand for sustainable packaging in cosmetics.

Pharmaceutical companies rely on collapsible tubes for packaging ointments, gels, and creams. The air-tight seals provided by ASME tubes ensure the product remains uncontaminated, meeting stringent health and safety standards. Additionally, the compact design of the tubes makes them convenient for patients to carry and use.

Collapsible tubes are increasingly popular in the food industry for packaging condiments, sauces, and edible pastes. ASME’s food-grade materials ensure the safety and freshness of the contents. The efficient dispensing mechanism minimizes waste, making these tubes a cost-effective solution for food manufacturers.

For industrial use, collapsible tubes are perfect for packaging adhesives, lubricants, and sealants. ASME’s robust designs ensure the tubes can handle the demands of industrial environments while providing precision dispensing for technical applications.

ASME is at the forefront of innovation in the packaging industry. The company continually invests in research and development to introduce new features and improve existing designs. Some of the latest innovations include:

ASME is committed to sustainability, utilizing biodegradable and recyclable materials in its collapsible tubes. This approach not only minimizes environmental impact but also appeals to eco-conscious consumers.

ASME employs state-of-the-art printing techniques to create visually appealing designs on collapsible tubes. High-resolution graphics and vibrant colors enhance brand visibility, making the packaging an effective marketing tool.

ASME is exploring smart dispensing technologies, such as integrated pumps and valves, to further enhance user experience. These features provide greater control over product flow, ensuring precision and convenience.

ASME Packaging Co., Ltd stands out as a reliable partner for businesses looking for high-quality collapsible tubes. Here are some reasons to choose ASME:

Custom collapsible tubes are revolutionizing the packaging industry by offering efficient product dispensing, sustainability, and versatility. ASME Packaging Co., Ltd has established itself as a leader in this space, providing innovative solutions to meet the diverse needs of its clients. By choosing ASME, businesses can benefit from cutting-edge designs, eco-friendly materials, and exceptional functionality. Whether you’re in cosmetics, pharmaceuticals, food, or industrial applications, ASME’s collapsible tubes are the ideal choice for efficient and sustainable packaging.

Tags:eco-friendly packaging solutions,Sunscreen Tube Packaging