Menu

Menu

Menu

In the ever-evolving world of cosmetics, the demand for natural and preservative-free products is at an all-time high. ASME Packaging Co., Ltd (hereafter referred to as ASME) has emerged as a leader in delivering innovative solutions tailored to meet this demand. One of the most groundbreaking advancements in this space is the cold aseptic filling technology. This method ensures the integrity, safety, and quality of natural cosmetic formulations while maintaining their efficacy and sustainability.

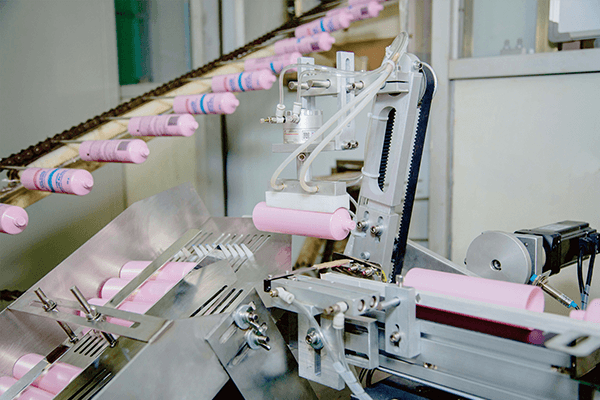

Cold aseptic filling technology is a process where cosmetic formulations are filled into tubes or containers under sterile conditions at low temperatures. This method is particularly beneficial for natural cosmetics, as it eliminates the need for high-temperature processing, which can degrade sensitive ingredients like essential oils, plant extracts, and vitamins. ASME has been at the forefront of integrating this technology into the production of natural cosmetic tubes, ensuring both product safety and environmental sustainability.

The natural cosmetics industry has witnessed exponential growth in recent years, driven by consumers’ preference for clean and sustainable beauty products. However, the production of these products poses unique challenges. Many natural formulations are free from synthetic preservatives, making them more susceptible to microbial contamination. Additionally, high-temperature filling processes can compromise the integrity of delicate natural ingredients.

This is where ASME’s cold aseptic filling technology comes into play. By maintaining sterile conditions and utilizing low-temperature processes, this technology preserves the active properties of natural ingredients while ensuring the product remains free from contaminants. It is a perfect harmony of science and nature, catering to the needs of both consumers and manufacturers.

The process of cold aseptic filling involves several key steps:

This meticulous process not only guarantees the safety and longevity of natural cosmetics but also aligns with the industry’s push toward sustainable and eco-friendly practices.

ASME’s cold aseptic filling technology offers numerous advantages, making it a preferred choice for natural cosmetic manufacturers:

As a pioneer in packaging technology, ASME is committed to delivering solutions that meet the highest standards of quality, safety, and sustainability. The company’s state-of-the-art facilities and experienced team ensure that every product filled using cold aseptic technology meets the specific needs of its clients and end consumers.

ASME also collaborates closely with cosmetic brands to develop customized solutions that align with their unique formulations and branding requirements. From tube design to filling and sealing, every aspect of the process is tailored to deliver exceptional results.

The adoption of cold aseptic filling technology is set to revolutionize the natural cosmetics industry. As consumers continue to prioritize clean and sustainable beauty products, manufacturers are under increasing pressure to innovate and adapt. ASME’s technology not only addresses these demands but also sets a benchmark for quality and sustainability in the industry.

Moreover, the use of advanced materials in cosmetic packaging, such as biodegradable and recyclable tubes, complements the cold aseptic filling process. ASME is actively exploring partnerships with material suppliers to further enhance the sustainability of its packaging solutions.

One of the key trends shaping the cosmetics industry is the shift toward sustainable packaging. With growing awareness of environmental issues, consumers are demanding eco-friendly alternatives to traditional plastic packaging. ASME has responded to this trend by offering innovative solutions such as recyclable and biodegradable tubes, which can be seamlessly integrated with cold aseptic filling technology.

Another emerging trend is the use of clean beauty formulations, which focus on transparency and the use of safe, non-toxic ingredients. ASME’s cold aseptic filling technology aligns perfectly with this movement, ensuring that natural cosmetics remain free from harmful contaminants and preservatives.

ASME Packaging Co., Ltd is redefining the standards of natural cosmetic production with its cutting-edge cold aseptic filling technology. By prioritizing the preservation of active ingredients, enhancing product safety, and promoting environmental sustainability, ASME is empowering cosmetic brands to meet the evolving needs of consumers.

As the industry continues to embrace innovation and sustainability, ASME remains at the forefront, delivering solutions that combine science, nature, and technology. Whether you’re a cosmetic manufacturer looking to elevate your product offerings or a consumer seeking high-quality natural beauty products, ASME’s expertise in cold aseptic filling technology is a testament to the future of clean and sustainable beauty.

For more information about ASME’s cold aseptic filling technology and sustainable packaging solutions, feel free to reach out to our team. Together, let’s shape the future of natural cosmetics.

Tags:eco-friendly packaging solutions,Sunscreen Tube Packaging