Menu

Menu

Menu

In the dynamic world of packaging, the choice between rotary and linear tube printing machines is pivotal for businesses aiming to optimize their production processes. ASME Packaging Co., Ltd (ASME) has been at the forefront of providing innovative solutions in this domain, offering state-of-the-art equipment that meets the diverse needs of the industry. This article delves into the intricacies of rotary and linear tube printing machines, highlighting their differences, advantages, and applications.

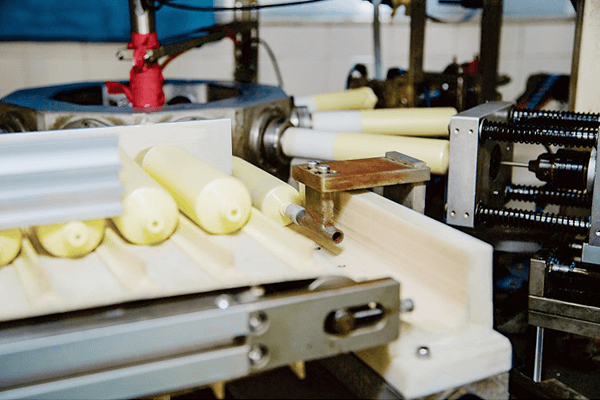

Rotary tube printing machines are renowned for their efficiency and speed, making them ideal for high-volume production environments. These machines operate on a continuous motion principle, where tubes are printed as they rotate around a central axis. This design allows for rapid printing, minimizing downtime and maximizing throughput.

d30 hair removal cream tube packaging

cosmetic tubes

foundation tube packaging

lip gloss pe tube packaging

ASME’s rotary tube printing machines are designed with precision engineering, ensuring reliability and durability. Their advanced technology incorporates automated features that reduce human error and enhance operational efficiency.

Linear tube printing machines, on the other hand, operate on a linear motion principle, where tubes are printed as they move in a straight line. This approach is often preferred for smaller production runs or when intricate designs are required.

ASME’s linear tube printing machines are equipped with cutting-edge technology that ensures high precision and adaptability. They are particularly suited for applications where customization and detail are paramount.

In recent years, the packaging industry has witnessed a surge in demand for sustainable and eco-friendly solutions. Both rotary and linear tube printing machines have adapted to these trends by incorporating features that reduce waste and energy consumption. ASME has been instrumental in driving these innovations, offering machines that align with the industry’s shift towards sustainability.

Additionally, the rise of digital printing technology has influenced the development of tube printing machines. Digital integration allows for greater customization and faster turnaround times, catering to the growing consumer demand for personalized products.

The decision between rotary and linear tube printing machines ultimately depends on the specific needs of a business. Factors such as production volume, design complexity, and space availability play a crucial role in determining the most suitable option.

| Criteria | Rotary Tube Printing Machines | Linear Tube Printing Machines |

|---|---|---|

| Production Volume | High | Low to Medium |

| Design Complexity | Moderate | High |

| Space Requirements | Larger | Compact |

ASME’s team of experts is committed to helping businesses make informed decisions by providing comprehensive consultations and tailored solutions. Whether opting for rotary or linear tube printing machines, ASME ensures that their clients receive equipment that enhances productivity and meets their unique requirements.

In conclusion, the choice between rotary and linear tube printing machines is a critical decision for any packaging business. ASME Packaging Co., Ltd offers a range of high-quality solutions that cater to the diverse needs of the industry, ensuring that businesses can achieve optimal efficiency and quality in their production processes. As the industry continues to evolve, ASME remains dedicated to innovation and sustainability, driving the future of packaging technology.