Menu

Menu

Menu

Luxury perfume packaging has always been a cornerstone of the fragrance industry. From elegant designs to innovative finishing techniques, the packaging not only protects the product but also enhances its perceived value. ASME Packaging Co., Ltd (ASME) has established itself as a leader in producing high-end perfume tubes with cutting-edge luxury finishing techniques that redefine sophistication.

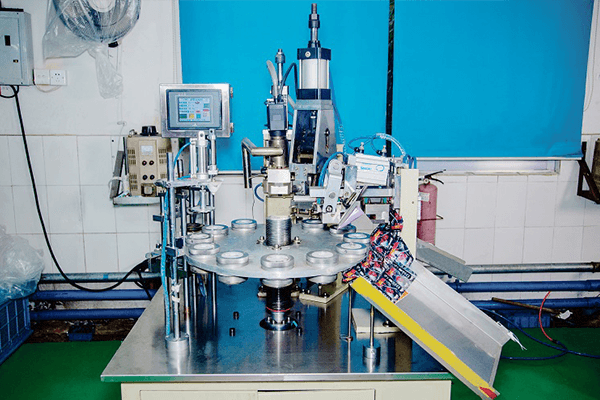

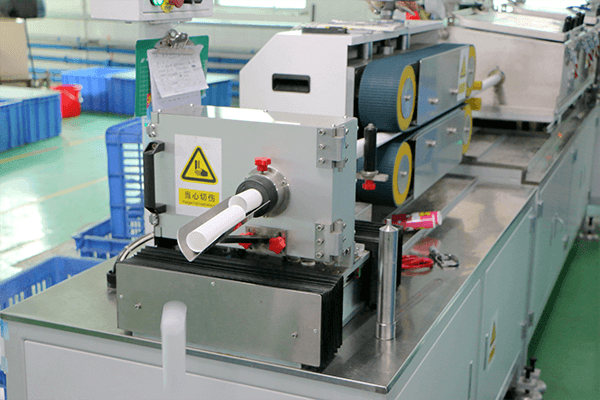

ASME specializes in delivering premium packaging solutions tailored to the needs of luxury brands. With a commitment to quality and innovation, the company has developed a range of finishing techniques that make perfume tubes stand out on retail shelves and captivate consumers.

ASME employs a variety of advanced finishing techniques to ensure that its perfume tubes meet the highest standards of elegance and durability. These techniques include:

Each of these techniques is executed with precision, ensuring that the final product reflects the brand’s vision and meets consumer expectations.

The perfume industry has witnessed significant changes in packaging trends over the years. Today, consumers expect not only high-quality fragrances but also packaging that complements the luxury experience. ASME stays ahead of these trends by incorporating sustainable materials and innovative designs into its offerings.

Sustainability has become a key focus in the packaging industry. ASME has responded to this demand by introducing eco-friendly materials and processes. Recyclable and biodegradable materials are now used in the production of perfume tubes, ensuring that luxury does not come at the expense of the environment.

Personalization is another growing trend in the industry. Consumers appreciate packaging that feels unique and tailored to their preferences. ASME’s advanced printing and finishing techniques enable brands to create customized designs that resonate with their target audience.

Metallic foiling is one of ASME’s signature techniques, offering a brilliant sheen that elevates the aesthetic appeal of perfume tubes. This process involves applying a thin layer of metallic foil to the surface, creating a reflective finish that exudes luxury. Metallic foiling is ideal for highlighting logos, text, or intricate patterns, making the packaging unforgettable.

UV coating, on the other hand, provides a protective layer that enhances the durability of the packaging. This technique not only adds a glossy finish but also safeguards the design against wear and tear. UV coating is particularly effective for maintaining the vibrancy of printed colors, ensuring that the packaging remains visually stunning over time.

ASME Packaging Co., Ltd has built a reputation for excellence in the luxury packaging industry. The company’s dedication to innovation, quality, and sustainability sets it apart from competitors. By continually investing in research and development, ASME ensures that its products remain at the forefront of industry trends.

Through partnerships with leading fragrance brands, ASME has demonstrated its ability to deliver packaging solutions that not only meet but exceed expectations. Whether it’s through metallic foiling, UV coating, or other advanced techniques, ASME is committed to creating packaging that enhances the consumer experience.

The world of high-end perfume packaging is evolving, and ASME Packaging Co., Ltd is leading the charge with its innovative finishing techniques. From metallic foiling to UV coating, ASME’s solutions combine functionality with luxury, making perfume tubes as captivating as the fragrances they hold.

As industry trends continue to shift towards sustainability and personalization, ASME remains committed to delivering packaging solutions that align with these values. For brands seeking to elevate their products and captivate consumers, ASME’s expertise in luxury finishing techniques is an invaluable asset.

With a focus on quality, innovation, and sustainability, ASME Packaging Co., Ltd is redefining the standards of luxury perfume packaging, ensuring that every detail contributes to an unforgettable experience.